How to correctly assemble and use the milk separator, instructions

The profitability of many farms is based on the sale of not only whole milk, but also dairy products. Special technology facilitates the processing of products, and how to assemble a manual or electric milk separator is indicated in the instructions supplied. For milk processing on large farms, it is advisable to use electric models.

Separator purpose

During the operation of the device, various fractions of milk are released. The main element of any design is a drum. Fat milk is separated into skim and cream by centrifugal forces, while the liquid is additionally purified.

An electric separator will help to qualitatively and quickly separate the cream. Small volumes of milk can be passed through a Soviet-style mechanical device. The manually operated separator copes with the preparation of butter from cream or sour cream.

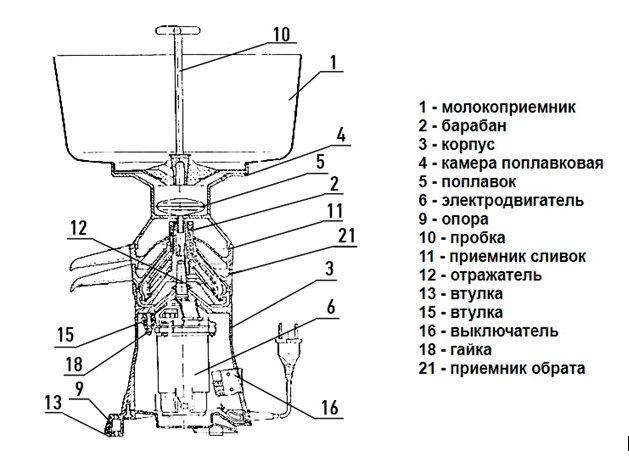

How to assemble a milk separator

Manufacturers offer a disassembled separator for purchase. The device is assembled in several stages.

- The drum is pushed onto the motor shaft. To check that there is no skew, the drum is rotated several times.

- A pair of drains is installed (one of the parts with a small groove is placed at the bottom, aligning the groove with the groove on the body).

- A float chamber is put on by placing a white plastic disk (float) inside.

- Install a large milk container.

Installing the valve plug is the final stage. The part has the form of a plastic tube with an L-shaped handle on one side, and an opening on the other that opens or closes the milk flow from the bowl.

Dismantling and assembly of the separator drum

Regular operation of the device involves periodic cleaning of the filter and drum from accumulating deposits. The disassembly and assembly procedure is performed in the following sequence:

- spin the drum with a key, then remove the cover from the case;

- the plates are removed, washed and wiped dry;

- take out the drum sealing gum, rinse and wipe;

- in order to wash the separating plate, a bolt is screwed on the upper cone of the drum to adjust the fat content;

- you need to assemble the drum in the reverse order, installing and carefully fixing all the components.

The owner of the device determines the cleaning periods independently. But this procedure cannot be neglected. As the accumulated deposits impair product quality, vibration will increase.

How to adjust the separator drum?

The fat content of the cream can be adjusted using a special adjusting screw. A special key is used to tune the drum by turning the bolt. To obtain a product with the maximum fat content, it is necessary to tighten the bolt until it stops and turn it slightly in the opposite direction. But it should be borne in mind that in order to obtain heavy cream, the separator can operate continuously for no more than 10-17 minutes. Then you need to flush the system as the drum and cymbals become clogged with fat.

When adjusting the drum, it must be borne in mind that the temperature of the poured milk also affects the receipt of the required product (the recommended temperature range is 30-40 ° C). Sometimes, when handling very high fat milk, the adjusting bolt will quickly become clogged. The best setting in this case is to completely unscrew the bolt and process the milk without it.

How does the device work?

Rotating, the drum creates centrifugal force, under the influence of which milk is separated in the inter-plate space. In this case, the fat is collected in the center, and the watery part is discarded. In this case, both cream and skim milk move up the drum, then flowing into special receivers.

Naturally, the separation procedure is faster when the drum rotates at high speeds.

How to choose a milk separator?

When choosing a model, you need to take into account the pros and cons of each type of separator (mechanical and electrical). The manual unit is valued inexpensively and allows you to process 40-50 liters of milk per hour. This is the best choice for farms with a small number of cows. The fat content of the resulting products is set manually.

Of the minuses, it should be noted the need to use manual labor, a low drum rotation speed (8.5-10 thousand rpm).

The advantages of electric models are obvious: high productivity (from 80 liters of milk per hour), the presence of sensors for adjusting the fat content of products, the function of disinfecting dairy products. The higher cost compared to manual units can be attributed to a minus.

How to use?

So that the quality of the final product does not disappoint, it is advisable to follow the instructions when using the technique. To process milk on the separator, several steps are taken step by step:

- the device is placed on a table. By means of a special key, the creamer is adjusted in height in order to obtain the desired fat content;

- heated or steamed milk is poured into the bowl. As soon as the drum of the electric separator spins at full speed (after 30-35 seconds), open the receiver tap;

- after processing the entire volume of milk, 2.5-3 liters of heated water is passed through the separator, washing the residues;

- then the equipment is turned off, disassembled and all components are thoroughly washed with a brush and a brush. The assembly (in reverse order) is started after all the elements have dried.

For the equipment to serve for a long time, you need to follow the recommendations for use indicated by the manufacturer. Periodic lubrication of the adjusting bolt is an important rule in the operation of both the electric and manual separator.

When choosing different models of equipment, you need to compare all performance characteristics. Since these parameters affect the quality of dairy products. But it should be borne in mind that heavy loads, poor-quality washing of parts also matter.